描述

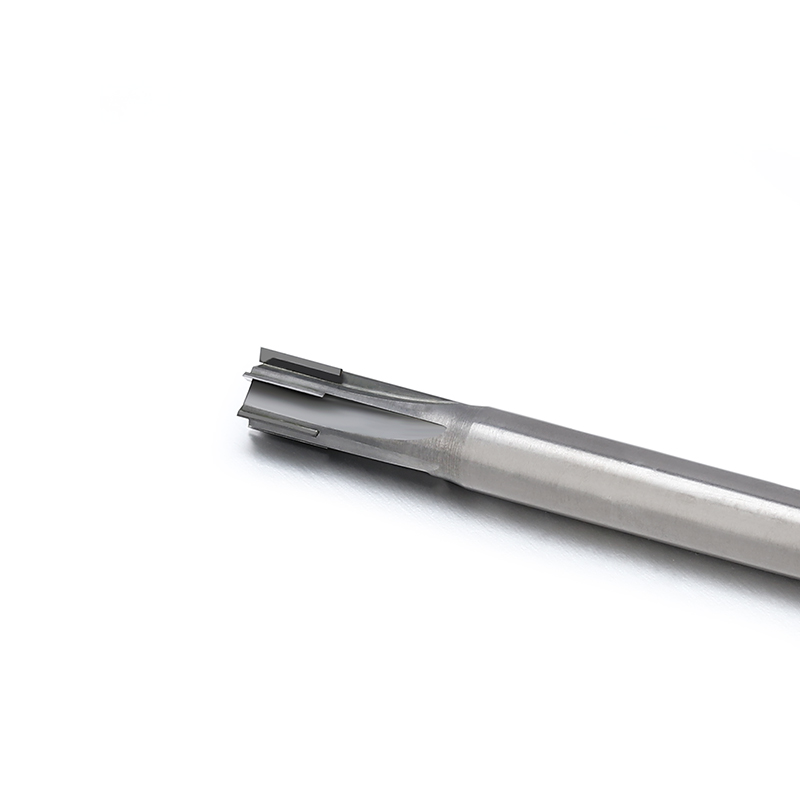

Solid Carbide PCD Milling Cutter

Diamond is the hardest material, using a special high temperature and high pressure process, a compact layer of polycrystalline diamond can be bonded to the cemented carbide substrate. This Solid Carbide PCD Milling Cutter can be used for cutting and machining of other metals that are not ferrous, such as aluminum and copper alloys, as well as non-metals such as fiber-reinforced plastics (GFK and CFK), hard rubbers, wood, fiberboards, melamine resin polymerized materials, and fiber-reinforced metals (MMC). . With diamond-coated cutting tools, you can achieve faster cutting speeds and longer tool life, as well as higher surface quality and machining accuracy of the material being machined.

ZHY CNC TOOLS

Product Parameters

| Name | ZHY end mill |

| Hardness | HRC 55~HRC68 |

| Flutes | 1/2/3/4/5/6 Flutes |

| Size | Our standard size or as request |

| Coating | Altin, Tialn, Tisin, Tin, DLC,Nano, Diamond |

| Public errand | 0-0.5μm |

| Suitable to process | Copper,cast iron,carbon steel,mould Steel, Stainless Steel, tool Steel, etc |

| OEM | OEM/ODM highly welcome |

End Mill Super Raw Material

| ltem Grade | HRC45 | HRC55 | HRC60 | HRC65 |

| Details | Grain size 0.7μm Co10% Flexural strength 3320N/mm² |

Grain size 0.6μm Co10% Flexural strength 4000N/mm² |

Grain size 0.5μm Co12% Flexural strength 4300N/mm² |

Grain size 0.5μm Co10% Flexural strength 4300N/mm² |

Super Coating

| Details | TiN | TiAIN | AITiN | TISIN | Nano Blue | DLC |

| Color | Golden | Purple | Black | antique brass | Dazzle blue | Dazzle black |

| HV | 2300 | 3200 | 3400 | 3600 | 42(GPA) | 1000~4000 |

| Thickness/μm | 0.4 | 0.5 | 0.5 | 0.4 | 0.4 | 0.5-2.0 |

| Friction coefficient | 0.4 | 0.35 | 0.4 | 0.45 | 0.4 | 0.05 |

| MAX Temperature | 500 | 800 | 900 | 1000 | 1200 | 400 |

| Description | cost-effective | General | High speed Hige HRC |

Processing opper, titanium, mold Steel |

General High Speed Cutting | non-ferrousmetals graphite andplastics |

Process

Tool edge passivation technology is an important issue that has not been generally recognized. It is so important because: after the passivation of the tool can effectively improve the edge strength, improve tool life and stability of the cutting process.

Description

The tool is used for the processing of computer hard disk cell phone and other bezel and shell, and aluminum, magnesium, Chin, silicon and other non-ferrous metal processing and some non-metallic materials, such as fiber materials, insulating materials, plastics, composites and so on.

Company Profile

Changzhou Zhengheyuan Cnc Tool Ltd was established in 2005, specializing in CNC tool cutters.We are leading enterprise in China. Our main products are milling cutter, drill bits, tool holder, inserts and other cnc accessories. We have many advanced CNC equipments machines, such as WALTER, ANCA and DECKEL. Our high quality CNC end mills and CNC tool holders are very popular with the majority of users, with high quality products, competitive prices and good our efficient service, we are confident to meet your needs.

ZHY factory

ZHY product quality inspection equipment

Our Advantage:

- 20 years specializing in cnc tools cutters

- 30+ pcs Walter, Anca, Dekel advanced production equipments

- 600W+ annual production capacity

- outstanding R&D teams, 50+ patents every year

- 20W+ sku milling cutters in stock

- 100% on time delivery

FAQ:

1. Are you manufacturer? Do you have factory?

Yes. We are manufacturer and have 20 years production experience in cnc tools. Main product: carbide end mill, srew taps, drills bits and so on.

2. Is free shipping possible?

We don’t offer free shipping service, but we will give you some discount if you buy large quantity products. And we have cooperation Express Companies, can offer you the best price of shipping cost.

If any interested in our products, pls feel free to contact us!